Introduction to Air Flotation Machine Equipment

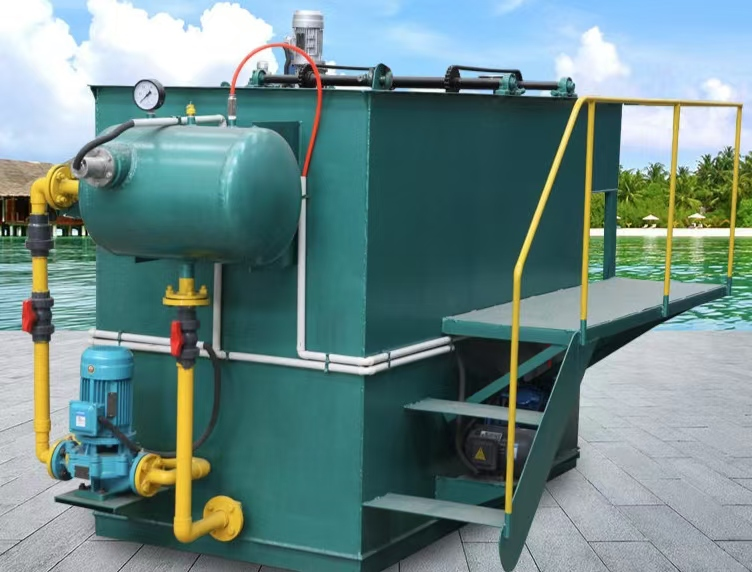

In the field of wastewater treatment, the air flotation machine is a highly efficient solid-liquid separation device. It operates by introducing a large number of microbubbles into the water, which attach to suspended particles. Leveraging the principle of buoyancy, these particles float to the water's surface, enabling solid-liquid separation and effectively removing impurities, suspended solids, and certain dissolved contaminants from the wastewater.

Working Principle

The air flotation machine operates primarily based on the principle of dissolved air flotation (DAF). Under specific pressure, air is dissolved into water through a dissolved air system to form saturated dissolved air water. When the dissolved air water is abruptly depressurized via a release device, the supersaturated air in the water is released as microbubbles, typically measuring 20–40 micrometers in diameter. These microbubbles rapidly adhere to pollutants such as suspended particles, colloids, and emulsified oil droplets in the wastewater, reducing the overall density of the pollutants below that of water. As a result, buoyancy causes the pollutants to float to the water surface, forming a scum layer, which is then scraped off by a scum removal device to achieve solid-liquid separation. The purified water is discharged from the bottom of the equipment.

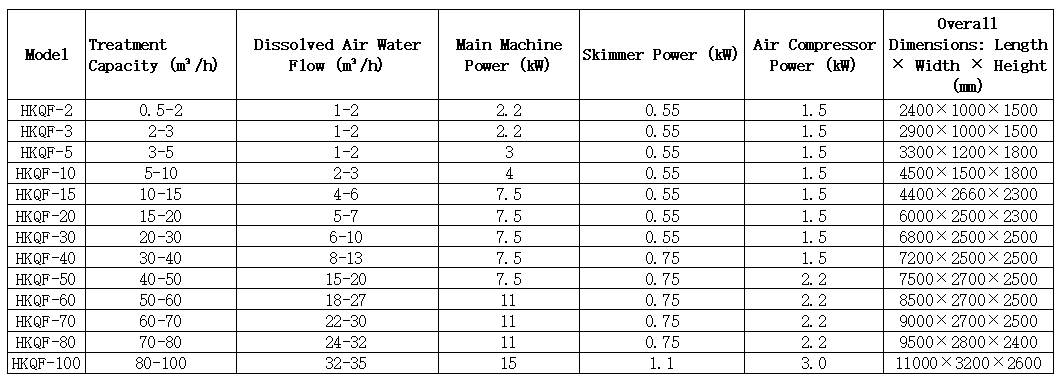

Specifications and Parameters

Treatment Capacity

The equipment's treatment capacity ranges from 1 m³/h to 100 m³/h, catering to sewage treatment demands of varying scales.

Equipment Material

Constructed from high-quality anti-corrosion carbon steel, the equipment boasts excellent corrosion resistance and durability, ensuring long-term stable operation.

Overall Dimensions

Operational Power

The operational power ranges from 0.5kW to 5kW, depending on specific configurations and treatment scales, featuring energy efficiency and high performance.

Model Selection & Customization

Air flotation machines of different models differ in treatment capacity, dimensions, and power configurations. The most suitable model can be selected based on factors such as actual sewage flow, water quality characteristics, and site conditions to meet diverse wastewater treatment needs. Meanwhile, our company also provides customized production according to clients' special requirements.

Application Scope

Domestic Sewage Treatment

As a pretreatment device for domestic sewage, it can effectively remove impurities such as suspended solids and floating matters, reduce the load on subsequent biochemical treatment units, and improve the overall treatment efficiency of sewage treatment plants. It can also be used for sludge thickening to reduce sludge volume, facilitating subsequent sludge transportation and disposal.

Water Supply Treatment

For raw water such as lake water and river water, it performs algae removal and turbidity reduction treatment, eliminating algae, plankton, and suspended particles in the water. This can purify the turbidity of domestic drinking water and industrial water to below 5 degrees, while also effectively reducing colority and oxygen consumption, ensuring the safety of water supply quality.