Introduction to Air Flotation Machine Equipment

The main body is crafted from high-quality stainless steel, offering exceptional corrosion resistance and abrasion tolerance. This enables the equipment to withstand diverse water quality conditions and harsh operating environments, significantly extending its service life while reducing maintenance costs and replacement frequency.

Working Principle

With the rotation of the drum, the intercepted impurities gradually move to the upper part, where a backwashing device installed above the drum uses high-pressure water (usually at a pressure of 0.2-0.4 MPa) to flush the screen, washing the impurities into the sludge collection hopper. The impurities are then discharged from the equipment through the slag discharge pipe, thus achieving a continuous filtration and sewage discharge process to ensure stable and efficient filtration performance.

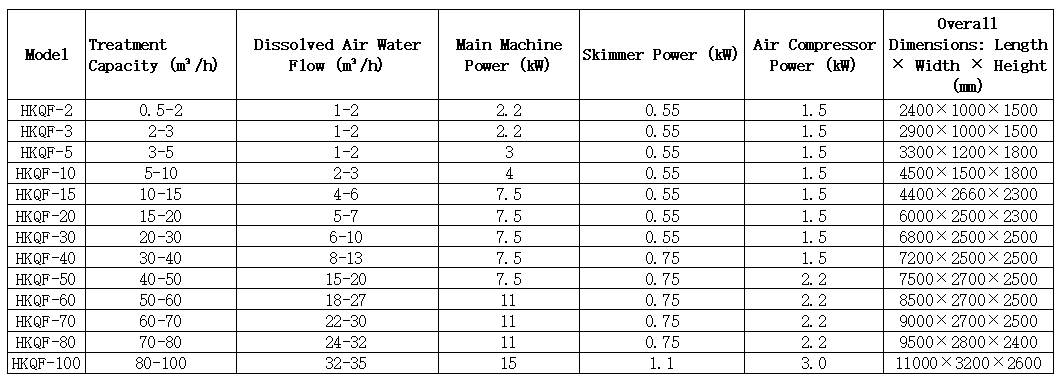

Specifications and Parameters

Durable Materials:

The main structure is constructed from high-quality stainless steel, offering excellent corrosion resistance and wear resistance. It can adapt to various complex water quality environments and harsh working conditions, significantly extending the equipment's service life while reducing maintenance costs and replacement frequency.

High-Efficiency Filter Screen:

Equipped with high-precision stainless steel screens featuring diverse aperture specifications (common ranges from 20 microns to 300 microns), allowing flexible selection based on different filtration needs. This ensures efficient interception of tiny impurities, high filtration accuracy, and stable and reliable effluent water quality.

Unique Drum Design:

The drum adopts a cylindrical structure with internal reinforcing ribs to ensure rigidity and stability during long-term operation. Meanwhile, the drum's rotation is controlled by a low-noise and low-energy consumption drive system, ensuring smooth operation, minimal noise, and low energy consumption.

Intelligent Automation:

Integrated with an automatic control system, it can achieve functions such as automatic flushing and automatic slag discharge, eliminating the need for frequent manual operation, reducing labor intensity, and improving work efficiency. It can also monitor and adjust the equipment's operating parameters in real time based on actual operation conditions to ensure the equipment always operates at its optimal state.

Compact Structural Design:

The equipment has a compact overall structure, small footprint, and convenient installation, flexibly adapting to various site conditions. It can easily fit into both new projects and retrofitting/upgrading of existing facilities.

Application Scope

Aquaculture Sector:

Widely used in freshwater and marine aquaculture ponds, as well as industrial recirculating aquaculture systems, it effectively removes suspended solids such as uneaten feed and fecal matter from aquaculture water, purifies water quality, reduces water eutrophication, creates a favorable growth environment for aquatic animals, increases stocking density and yield, and reduces the likelihood of disease outbreaks.

Industrial Wastewater Treatment:

Suitable for the pre-treatment stage of industrial wastewater generated by industries such as food processing, slaughtering, dyeing, papermaking, and chemical production. It can rapidly intercept large particulate suspended solids, fibers, hair, and other impurities in wastewater, reduce the load on subsequent treatment processes, improve overall sewage treatment efficiency, and lower treatment costs.

Municipal Sewage Treatment:

In the influent pre-treatment phase of municipal wastewater treatment plants, rotary drum micro-filters effectively remove floating matter and coarse suspended solids from sewage, protect downstream treatment equipment, prevent pipeline blockages and equipment damage, and enhance the biodegradability of sewage, providing favorable conditions for subsequent treatment processes.

Landscape Water Treatment:

Used for water quality purification in landscape water bodies such as park lakes, artificial water features, and golf course ponds. It removes impurities such as fallen leaves, algae, and plankton, maintains clear and transparent water, enhances landscape aesthetics, and preserves the ecological balance of water bodies.