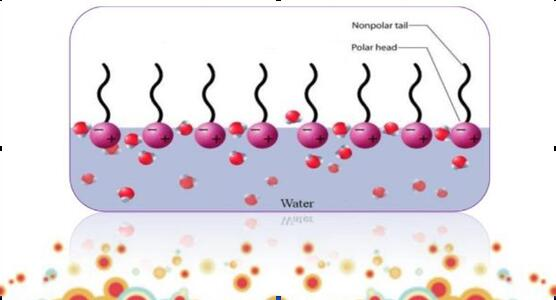

Surfactants possess excellent properties such as detergency, wetting, emulsification and solubilization. Surfactant-containing wastewater comes from a wide range of sources — for example, domestic kitchen wastewater, hotel wastewater and laundry wastewater all contain anionic surfactants (LAS), while industries like detergent manufacturing, chemical engineering and textiles also generate large quantities of surfactant-laden wastewater.

Wastewater Quality

Surfactants in the wastewater are mostly anionic, dominated by linear alkylbenzene sulfonate (LAS). In addition to surfactants and colloidal pollutants emulsified and carried by them, the wastewater also contains auxiliaries, bleaching agents, oils and other substances. The wastewater is generally alkaline, with surfactant content varying significantly — up to 1000 mg/L in wool washing wastewater, for example, and only a dozen mg/L in bathing wastewater. The COD value also differs greatly, ranging from several hundred to tens of thousands of mg/L or even higher. Surfactant-containing wastewater is widely prevalent, and its treatment is of great significance for protecting resources, maintaining ecological balance, and promoting economic development.

Wastewater from the production processes of fine chemical enterprises — such as those manufacturing daily chemical products, oils and fats, printing and dyeing auxiliaries, and surfactants — includes floor washing wastewater, reactor cleaning wastewater, and production wastewater, all of which contain large amounts of surfactants. This type of wastewater exhibits high biological toxicity, low B/C ratio, and poor biodegradability. Moreover, due to the diversity of products produced, the pollutants in the production wastewater vary greatly and often include special refractory substances. The COD of the wastewater is generally several thousand to tens of thousands of mg/L, and sometimes exceeds 100,000 mg/L. It is characterized by excessive foaming, with pollutants fully dissolved in the water.

Hazards of Surfactant Wastewater

LAS is a biologically refractory substance and is classified as a Category II pollutant in China's environmental standards. After being used, most surfactants eventually form emulsified colloidal substances that are discharged into the natural environment with wastewater. LAS, as the primary pollutant, combines with other pollutants to form colloidal particles with a certain degree of dispersibility after entering water bodies. Anionic surfactants can inhibit and kill microorganisms, and also hinder the degradation of other toxic substances. Meanwhile, surfactants cause foaming in water, which reduces the reoxygenation rate and oxygenation level of the water, deteriorating water quality. If directly discharged into water bodies without treatment, it will lead to eutrophication of lakes, rivers and other water bodies. LAS can also emulsify other pollutants in water, increasing their concentration and toxicity, thereby causing indirect pollution. Surfactant production wastewater, as well as LAS-containing wastewater such as kitchen wastewater, bathing wastewater and laundry wastewater, pose significant chronic hazards to animals, plants and humans.

Treatment Methods

Coagulation-Biochemical Process for Surfactant Wastewater Treatment

After impurities are intercepted by a grille, the wastewater enters an equalization tank and is lifted to a coagulation reactor by a submersible pump. Inorganic coagulant PAC (Polyaluminum Chloride) and organic flocculant CG-A are injected into the lifting pipeline via metering pumps to achieve effective mixing with the wastewater. The coagulation reactor adopts a plug-flow design, with the cross-sectional area of the reaction channel gradually increasing to realize decreasing coagulation. Subsequently, the wastewater flows into a sedimentation tank for solid-liquid separation. Before entering the hydrolytic acidification tank, the supernatant is adjusted to a pH of 8–9 with alkali depending on water quality, and the treated water is discharged after undergoing hydrolytic acidification, contact oxidation, and sand filtration.

The biological contact oxidation tank adopts a two-stage contact oxidation process, equipped with plum-blossom-shaped three-dimensional packing. The two aerobic tanks can be operated in parallel or series, with switching possible according to water quality and effluent standard requirements.

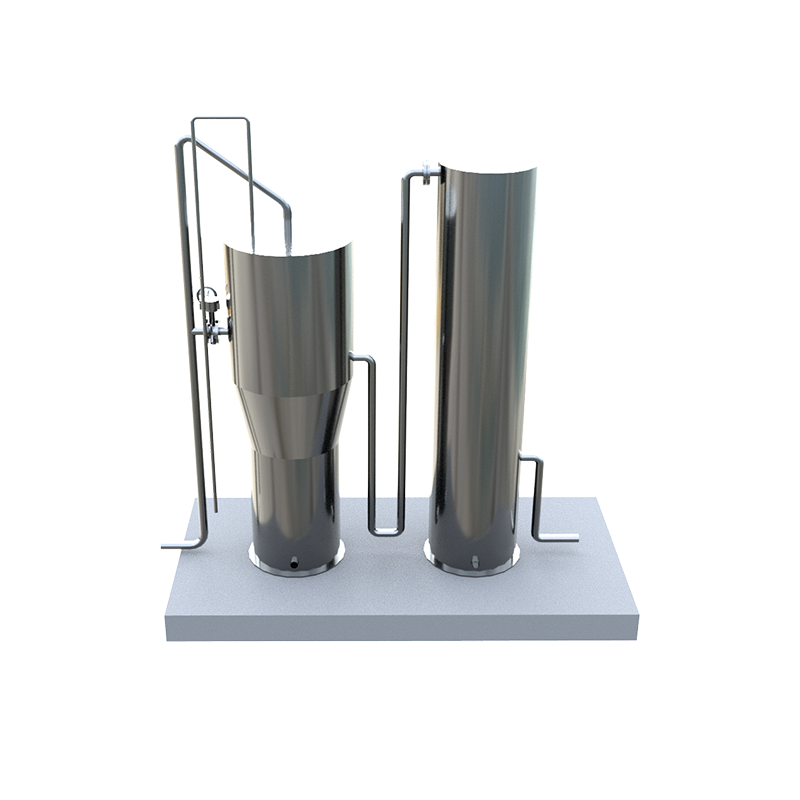

Foam Separation Method

The foam separation method refers to a process where air is introduced into the wastewater to generate bubbles, allowing LAS in the wastewater to adsorb onto the bubble surfaces, rise to the water surface for enrichment to form a foam layer, and then the foam layer is removed to concentrate and separate LAS from the wastewater. This method has been industrialized in China and operates stably. The separated foam can be removed using defoamers (such as silicone), vacuum systems, or mechanical defoamers, and the concentrate can be reused or further treated. Currently, the COD removal rate of foam separation is relatively low (only about 50%), so it needs to be combined with other methods.

Membrane Separation Method

The membrane separation method utilizes the high permeation selectivity of membranes to separate solvents and solutes in solutions. Ultrafiltration (UF) and nanofiltration (NF) technologies in membrane separation can be used to treat LAS-containing wastewater. When LAS in the wastewater mainly exists in molecular and ionic forms, nanofiltration technology achieves better treatment effects.

Adsorption Method

Adsorbents used in the adsorption method mainly include activated carbon, adsorption resins, diatomite, kaolin, etc. At room temperature, the activated carbon method exhibits good treatment effects on surfactant wastewater — the adsorption capacity of activated carbon for LAS can reach 55.8 mg/g, and the adsorption process conforms to the Freundlich equation. However, activated carbon regeneration consumes high energy, and its adsorption capacity decreases to varying degrees after regeneration, thus limiting its application.

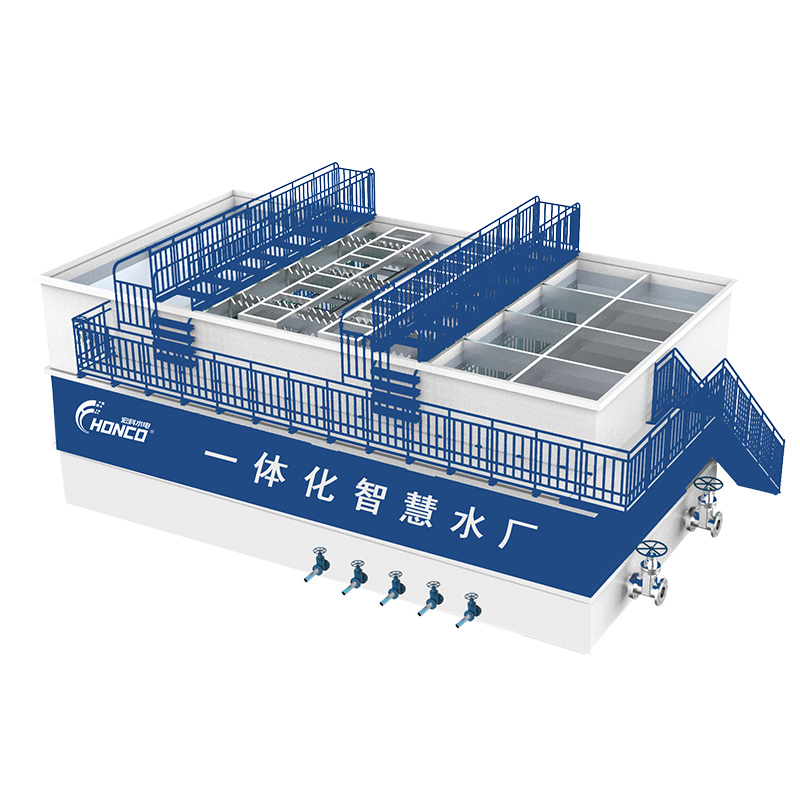

Surfactant Wastewater Treatment Equipment