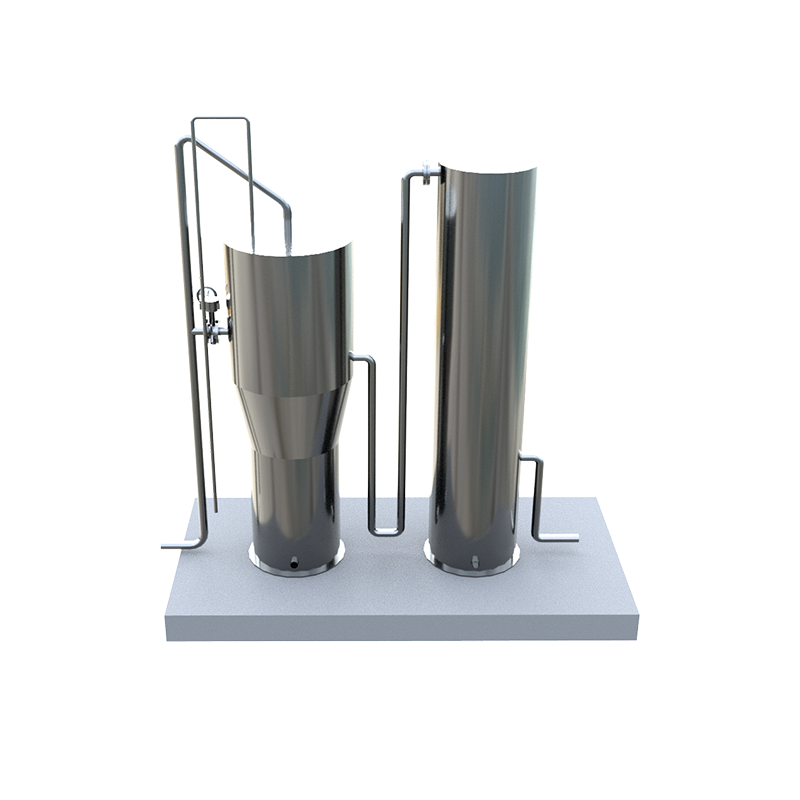

Product Overview

The integrated stainless steel water purifier is a compact water treatment device that integrates multiple water purification processes. Made of food-grade 304/316L stainless steel, it incorporates water purification procedures such as flocculation, sedimentation, filtration and disinfection into a single piece of equipment. It can efficiently treat various water sources and provide safe, clean water for household, commercial and industrial users.

Core Advantages

Outstanding Material Properties

Food-grade 304/316L stainless steel: Non-toxic, odor-free, and free from heavy metal leaching risks, complying with international food safety standards.Super corrosion resistance: Resistant to erosion by residual chlorine, acids and alkalis in water, making it particularly suitable for coastal areas and industrial environments.High-temperature stability: Capable of withstanding temperatures above 300℃, ideal for hot water supply systems.Long-service-life design: Boasts a service life of over 30 years, eliminating the need for regular anti-corrosion maintenance and reducing long-term operational costs.

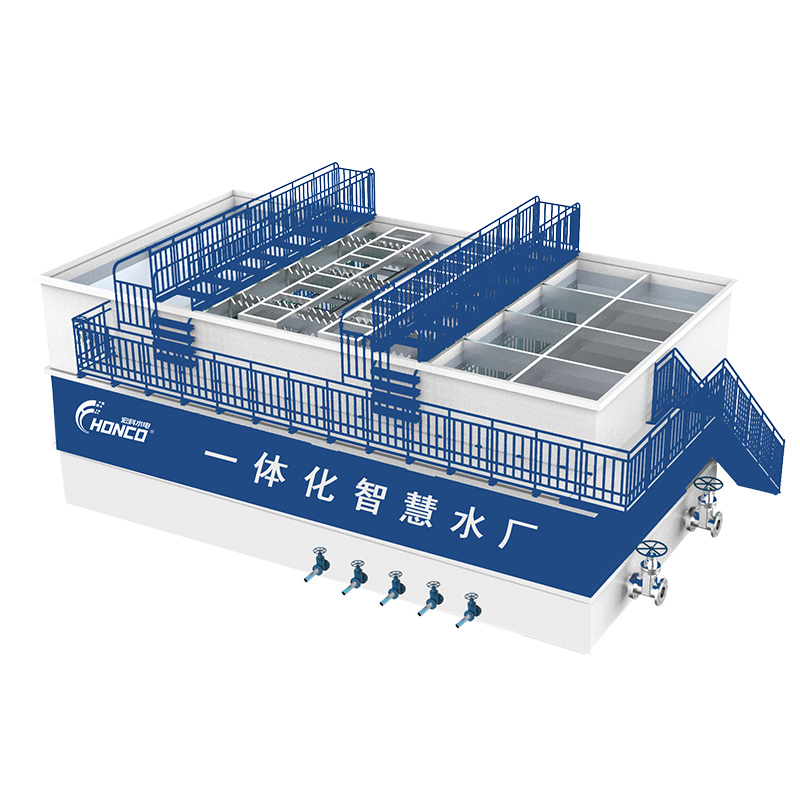

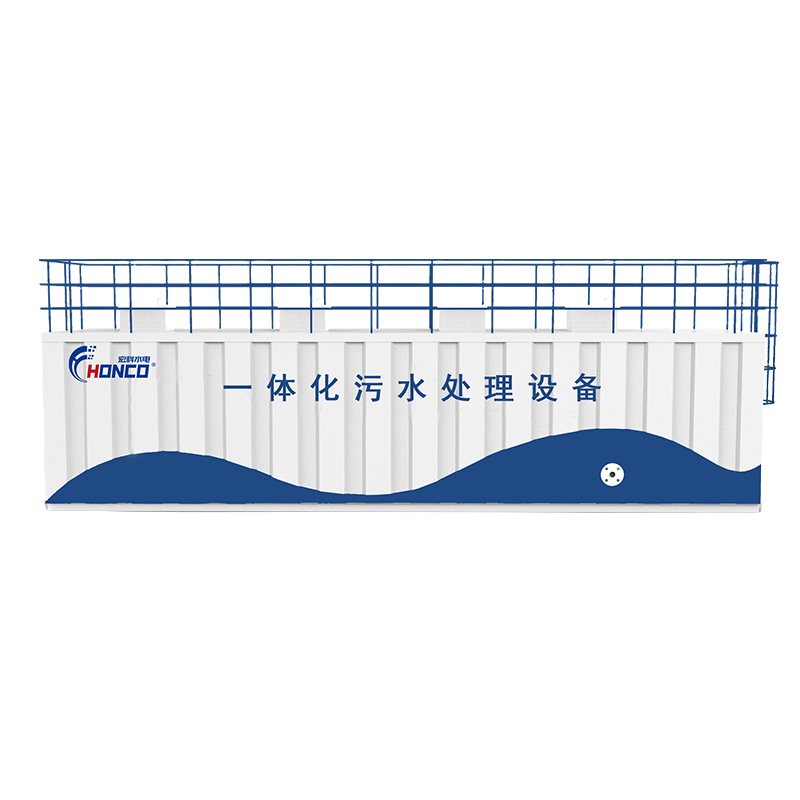

Advantages of Integrated Design

Compact size & small footprint: Occupying only 1/3–1/5 of the space of traditional water purification plants, it is suitable for space-constrained locations.Modular structure: Reasonable layout of each functional unit ensures easy installation and maintenance, and supports customized configurations.Fully automatic operation: Equipped with a PLC intelligent control system, it realizes automatic backwashing and sewage discharge, reducing manual intervention and maintenance workload.

Excellent Water Purification Performance

High-efficiency impurity removal: Capable of treating raw water with turbidity up to 3000mg/L, with the effluent turbidity ≤ 0.5–1 NTU, which is superior to national standards.Comprehensive purification: Effectively removes sediment, colloids, suspended solids, bacteria, viruses and partial heavy metals.Stable water output: Features minimal water quality fluctuation (≤ 0.2 NTU), suitable for application scenarios with stringent water quality requirements.

Working Principle

The integrated stainless steel water purifier adopts the core technical route of multi-stage purification + intelligent control:

Pretreatment Stage: After raw water enters the device, it first fully contacts the flocculant in the mixer to form flocs.

Core Treatment Stage:

Reaction Zone: A special mechanical auxiliary mixing structure is adopted to accelerate the flocculation reaction.

Sedimentation Zone: Inclined tube sedimentation technology is used to efficiently separate suspended solids from clear water.

Filtration Zone: Multi-media filtration with quartz sand, activated carbon, etc., is employed to intercept residual impurities.

Disinfection Zone: Optional UV sterilization or chlorine disinfection ensures that the effluent meets microbial index standards.

Intelligent Control:

Automatically monitors water quality parameters and adjusts the operating status in real time.

Triggers backwashing regularly or by pressure difference to automatically remove contaminants trapped by the filter media and extend the service life of the filter element.

Automatically alarms in case of faults for easy maintenance.

Application Scenarios

Household / Civilian Sector

Whole-house Water Purification: Installed on the incoming water pipeline to purify domestic water for the entire household and protect water-using appliances.

Direct Drinking Water System: Provides safe, odor-free drinking water, ideal especially for infants, the elderly and people sensitive to water quality.

Villas / High-end Residences: Improves the quality of life and meets the high demand for healthy drinking water.

Commercial Premises

Hotels / Restaurants: Supplies high-quality water for kitchens and guest rooms to enhance service quality.

Hospitals / Clinics: Meets the stringent hygiene and safety requirements for medical water use.

Schools / Office Buildings: Provides healthy drinking water for teachers, students and employees, and improves the working and learning environment.

Industrial Applications

Food and Beverage Processing: Meets the strict standards for iron and manganese content in production water to ensure product quality.

Electronic Industry: Supplies high-purity pretreated water for chip manufacturing and display tube production.

Pharmaceutical Industry: Preparation of process water that complies with GMP standards.

Boiler Make-up Water: Reduces scale formation, extends equipment service life and improves thermal efficiency.

Public Facilities / Special Scenarios

Rural Centralized Water Supply: Addresses drinking water safety issues in remote areas, with a treatment capacity of 5–50 tons per hour.

Temporary Water Supply: Emergency water source treatment for construction sites, field operation sites and disaster relief areas.

Scenic Spots / Resorts: Provides safe drinking water for tourists and supports the operation of water recreation facilities.

Technical Parameters

| Parameter | Description |

| Material | Main body: Food-grade 304/316L stainless steel; Internal pipeline: Food-grade stainless steel/non-toxic plastic |

| Treatment Capacity | Household: 100-2000L/h; Commercial: 2-50 tons/h; Industrial: 50-500 tons/h (customizable) |

| Water Inlet Requirements | Water source: Rivers/lakes/reservoirs/well water/tap water; Turbidity: ≤3000mg/L; Temperature: 5-45°C |

| Water Outlet Standard | Complies with Sanitary Standard for Drinking Water (GB5749-2022); Turbidity: ≤0.5-1NTU; Total bacteria: ≤10CFU/mL |

| Working Pressure | 0.15-0.4MPa |

| Power | 50-5000W (varies by treatment scale) |

| Control Mode | PLC full automatic/manual optional; supports remote monitoring (optional) |

| Dimensions | Determined by treatment capacity; height usually ≤3 meters (space-saving) |

| Weight | 100kg to several tons (depends on model) |

International Market Advantages

Differentiated Competitive Highlights

Material Safety: Compared with plastic-cased water purifiers, stainless steel material poses zero leaching risk and complies with the stringent food safety standards of Europe and the United States.

Durability: Boasting a service life of 30 years, it far outperforms ordinary plastic water purifiers (5–8 years), reducing users’ long-term ownership costs.

Corrosion Resistance: Especially suitable for diverse water quality conditions worldwide, particularly in high-salt and high-chlorine areas (e.g., coastal countries).

Environmental Sustainability: The material is recyclable and reusable, aligning with the global trend of environmental protection.

International Certification Support

The product can provide the following certifications (selected according to target markets):

EU: CE Certification (including RoHS and REACH), EN 14898 (hygienic performance), EN 1276 (microbiological standards).

North America: NSF/ANSI 42/53/61 Certifications, EPA Certification.

Others: WQA (Water Quality Association) Certification, Australia WaterMark Certification.

Purchase Guide

Choose Based on Water Demand

Household Use: Select models with a treatment capacity of 1000–2000 L/h; 304 stainless steel is fully sufficient.

Small-scale Commercial Use: Opt for 2–10 tons/h capacity; 316L stainless steel is recommended for enhanced corrosion resistance.

Industrial/Large-scale Applications: Choose capacities above 10 tons/h; professional customization is required, with 316L or duplex stainless steel as the top priority.

Choose Based on Raw Water Characteristics

Surface Water (rivers, lakes): Prioritize models equipped with flocculation and sedimentation functions.

Groundwater: Consider adding iron and manganese removal or water softening modules.

Seawater/High-salt Areas: 316L stainless steel is a must to resist chloride ion corrosion.

Key Configuration Recommendations

Filter Cartridge Combination: Adopt multi-stage filtration (PP cotton + activated carbon + ultrafiltration/RO) to ensure effluent quality.

Control Method: Prioritize PLC fully automatic control to reduce manual maintenance work.

Additional Functions: Optional UV sterilization, water quality monitoring, remote control, etc., are available based on specific requirements.

Installation & Maintenance

Easy Installation

Compact footprint, suitable for indoor or outdoor installation (protective model available).

Only requires connection of inlet/outlet pipelines and power supply, with no complex construction needed.

The equipment is fully commissioned before leaving the factory and can be put into use immediately after on-site connection.

Low-Maintenance Design

Equipped with an automatic backwashing system to reduce manual intervention.

Modular design allows independent replacement of individual components.

Quarterly inspection and annual comprehensive maintenance are recommended.

Packaging & Transportation

Standard Export Packaging: Wooden cases with moisture-proof film to ensure transportation safety.

Firm internal fixation to prevent damage caused by shaking during transit.

Customizable packaging solutions are available according to customer requirements, adapting to different transportation modes (sea/air/land freight).

Conclusion

With its outstanding durability, comprehensive water purification capability and sleek appearance, the integrated stainless steel water purifier has become a premium choice in the global water treatment market. Whether you are a household user pursuing healthy drinking water, or a commercial/industrial client seeking a stable and efficient water treatment solution, this product can meet your needs. It provides a guarantee of safe and clean water supply while reducing long-term operational costs.

Next Step

Contact us to get a customized solution, and let us provide you with the most suitable integrated stainless steel water purifier solution for your specific requirements.