China has a large rural population and a relatively low level of economic development. Currently, a large amount of domestic sewage generated by rural residents is mainly discharged directly without treatment. Compared with urban areas, rural domestic sewage shows significant differences in water quality and quantity. Affected by factors such as economic conditions, living habits, regional climate, and geographical environment, the water quality and quantity of rural domestic sewage exhibit great volatility. In view of the characteristics of rural domestic sewage and the practical situation of low operation and maintenance management levels of treatment facilities, the use of traditional activated sludge process is prone to problems such as "inadaptability to local conditions" and sewage treatment facilities "being left idle". Therefore, it is necessary to develop process technologies and equipment suitable for decentralized rural sewage treatment.

The biofilm process has the advantages of strong shock resistance, low sludge production, and simple operation and maintenance. At present, there are some facilities using biofilm processes to treat rural domestic sewage, but there are still some problems in operation. For example, the biological contact oxidation process is prone to uneven aeration and water distribution, as well as filler clogging; biofilters require regular backwashing, resulting in relatively complex operation and management; rotating biological contactors have high investment costs and great difficulties in operation and maintenance. Polyester fiber is a commonly used material for biofilm carriers at present, which has the characteristics of being not easily degraded by microorganisms, uniform pore distribution, and good biofilm formation performance. Selecting polyester fiber as the modular filler and designing the module into the form of a three-dimensional immobilized biofilm curtain can provide the module with abundant circulation channels to avoid clogging. Meanwhile, the modular and assembled form enables quick installation and a short construction period. Based on this, the authors developed a three-dimensional immobilized biofilm reactor with polyester fiber as the filler. The effects of filler packing ratio, anoxic zone mixing method, and hydraulic retention time (HRT) on the treatment efficiency of rural domestic sewage by this process were investigated through pilot-scale tests, and the nitrogen removal mechanism of the reactor was analyzed from a microbiological perspective, aiming to provide technical reference for the treatment of decentralized rural domestic sewage.

1. Materials and Methods

1.1 Test Water and Inoculated Sludge

The test used the grid effluent from a water purification plant in Shenzhen to simulate rural domestic sewage. During the test period, the COD, NH₄⁺-N, TN, and SS concentrations of the influent to the reactor were 96.08~492.90 mg/L, 16.70~46.10 mg/L, 20.13~49.19 mg/L, and 40~352 mg/L, respectively. The designed effluent quality complies with the Class 1A standard of the Guangdong Provincial Local Standard Discharge Standard of Pollutants for Rural Domestic Sewage Treatment (DB44/2208—2019). The inoculated sludge was taken from the dewatered sludge of the same water purification plant (moisture content: 79.6%). The dewatered sludge was added to the reactor, followed by continuous closed aeration for 48 hours before water feeding and operation.

1.2 Test Equipment and Operation Mode

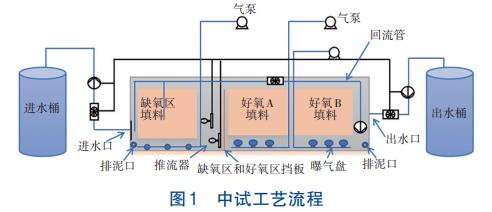

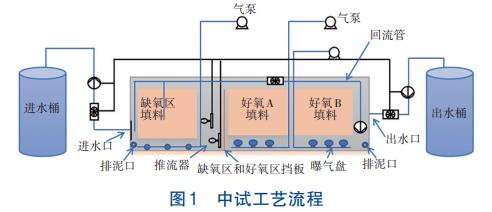

The designed treatment capacity of the test equipment was 6 m³/d. The process flow is shown in Figure 1: one module was installed in the anoxic zone, and two modules in the aerobic zone. A direct-flow water pump was used to pump the sewage from the inlet tank into the anoxic zone, which then overflowed through the top baffle into the bottom of the aerobic zone. The water outlet of the aerobic zone was set at the end of the reactor, and the nitrified liquid from the aerobic zone was refluxed to the front end of the anoxic zone through a reflux pipe for denitrification. The reactor operated with a pure biofilm process. Sludge discharge ports were set at the front and rear ends of the reactor for regular sludge discharge, and no secondary sedimentation tank was installed.

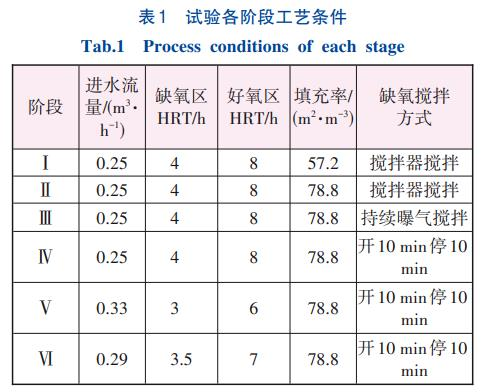

1.3 Optimization of Test Operation Conditions

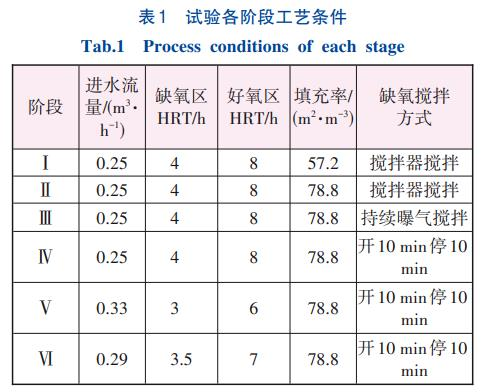

The test investigated the effects of parameters such as filler packing ratio, anoxic zone mixing method, and HRT on the treatment efficiency of the three-dimensional immobilized biofilm reactor. The reactor operated for a total of 6 months, divided into 6 phases, and the operating conditions of each phase are shown in Table 1. In Phases Ⅰ and Ⅱ, filler packing ratios of 57.2 m²/m³ and 78.8 m²/m³ were adopted respectively to explore their impacts on pollutant removal efficiency; in Phases Ⅱ and Ⅲ, stirrer and perforated pipe aeration were used for mixing in the anoxic zone respectively to study the effects of different mixing methods on the DO concentration in the anoxic zone and pollutant removal efficiency; in Phases Ⅲ and Ⅳ, the pollutant removal effects of continuous aeration and cyclic operation mixing mode (10 minutes on and 10 minutes off) were compared; in Phases Ⅳ, Ⅴ, and Ⅵ, the total HRT was adjusted to 12 h, 9 h, and 10.5 h respectively to explore the maximum treatment capacity of the reactor under the condition of ensuring the effluent quality meets the standard. During the operation period, the nitrified liquid reflux ratio was set to 200%.

1.4 Test Items and Methods

1.4.1 Determination of Routine Indicators

Water samples from inlet and outlet were collected regularly to determine indicators such as COD, NH4+-N, NO3--N, TN and SS. Meanwhile, DO concentration and biofilm biomass on fillers were tested regularly.

COD was determined by the standard potassium dichromate method.

NH4+-N was measured using the Nessler's reagent spectrophotometric method.

TN was determined via the alkaline potassium persulfate oxidation-ultraviolet spectrophotometric method.

NO3--N was measured by the ultraviolet spectrophotometric method.

SS was determined through the gravimetric method.

In different positions of anoxic zone and aerobic zone, 50mm×50mm fillers were sampled for multiple times. The sludge on the fillers was extracted using an ultrasonic cleaner, and the biomass per unit area of the filler was determined by the gravimetric method, so as to calculate the biomass in the reactor. DO was detected with a portable dissolved oxygen meter.

1.4.2 Microbiological Analysis

In Phases Ⅱ, Ⅲ and Ⅳ, 50mm×50mm fillers were randomly sampled from anoxic tanks and aerobic tanks respectively, and the biofilm on the fillers was extracted by an ultrasonic cleaner.

Samples from the anoxic zone were named A1, A2 and A3 respectively.

Samples from the aerobic zone were named O1, O2 and O3 respectively.

The biofilm samples were placed in absolute ethanol with a volume ratio of 1∶1, and sent to the -80℃ ultra-low temperature refrigerator in the laboratory within 1 hour. The DNA of microorganisms in the biofilm was extracted in accordance with the instructions in the FastDNATM Spin Kit for Soil. The extracted samples were sent to Shanghai Maji Biomedical Technology Co., Ltd. for sequencing analysis.